Table of Contents

Families with children should all have purchased wooden toys or teaching tools at some point. Wood is a natural material that, unlike plastic, can degrade in the environment. Therefore, wooden toys have always had a place in the toy market.And so many people want to know how to make wooden toys?

When it comes to the wooden toy industry, Zhejiang Yunhe cannot be ignored, known as the “Hometown of Chinese Toys.” Yunhe is the largest domestic manufacturing and export base for wooden toys, with over 1,000 wooden toy production enterprises in the county and more than 31,000 employees. Wooden toys from Yunhe account for 40% of the world market.

Some enterprises in Yunhe have moved beyond the traditional manufacturing model. They produce their own animated films featuring wooden characters, using cultural products to drive the sales of wooden toys.

Now, let’s take a look at the main manufacturing processes of wooden toys.

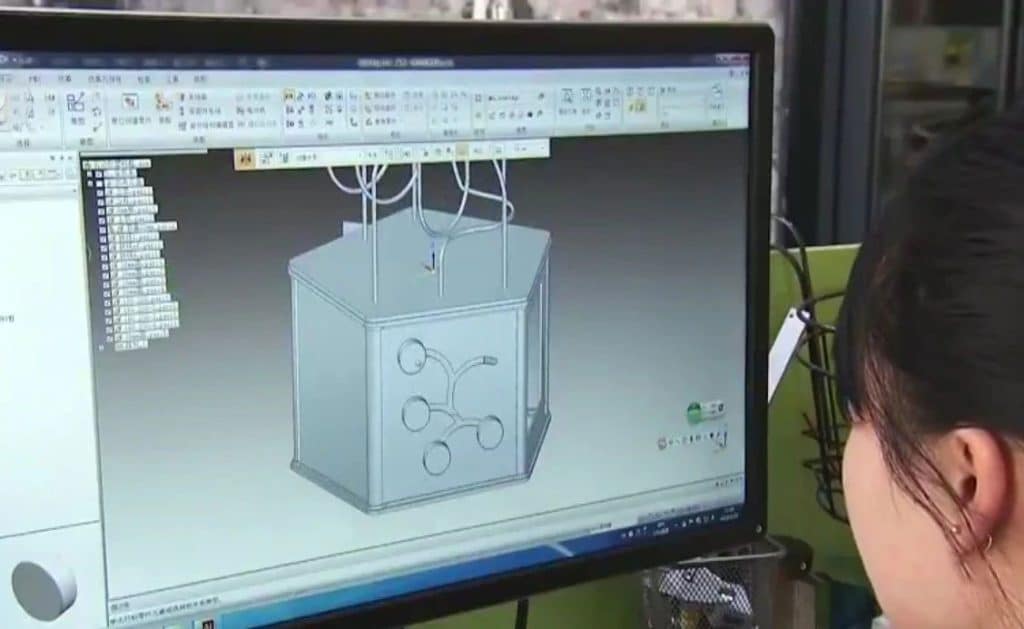

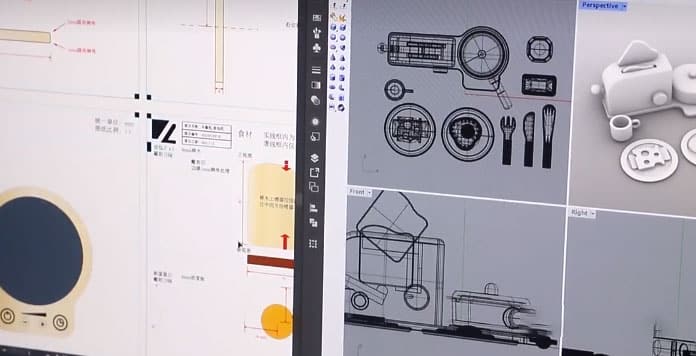

Development and Engineering

- Development and Engineering – Modeling and Drawing

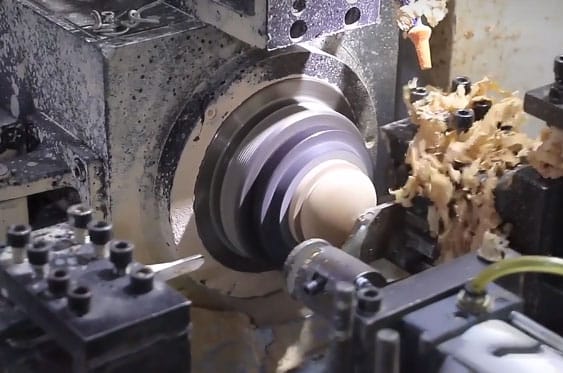

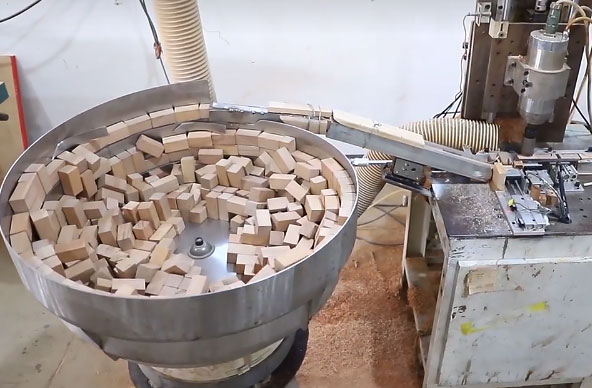

Material Forming

- Material Forming – Dust Removal Facilities in Forming Workshop

- Material Forming – Wood Cutting

Material Forming – Carving

Surface Treatment

- Surface Treatment – Automatic Polishing

- Surface Treatment – Polishing

- Surface Treatment – Painting

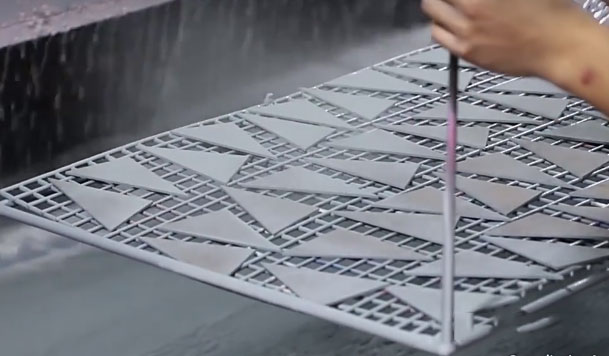

- Surface Treatment – Screen Printing

- Surface Treatment – Heat Transfer Printing

Assembly

- Assembly

Post-Processing

- Post-Processing – Packaging

Inspection and Testing

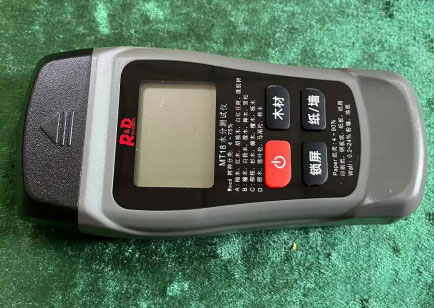

- Inspection and Testing – Moisture Measurement

- Inspection and Testing – Tensile Testing

- Inspection and Testing – Pointed Tip Testing